Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

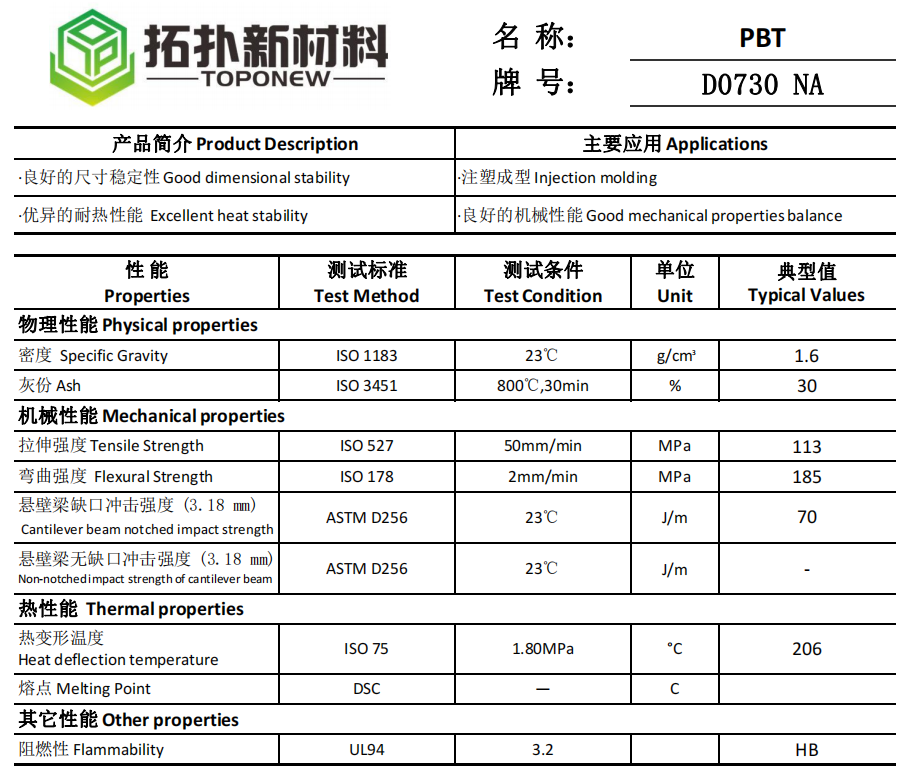

PBT D0730

Glass Filled: 30%

(Custom materials available according to your Technical Data Sheet)

- Product Details

-

Download

Customizable Materials Available:

- Color (Customization of plastic pellet color according to your requirements.)

- Flame retardant grade (Let us know which flame retardant level you need: 0.8mm-3.0mm HB, V0, V1, V2, 5VA, 5VB)

- Glass fiber reinforcement material (10%-50% availability)

- Carbon fiber reinforcement material (10%-50% availability)

- UV resistance property (Tell us the application scenarios or UV resistance level of the materials )

- Other materials can also be customized ( Just need to provide your Technical Data Sheet. )

The Technical Data Sheet of PBT D0730

Welcome to our discussion on PBT GF30 material PBT D0730- a specialized type of material that is 30% glass-filled and known for its excellent properties. This material is commonly used in the production of light bulb bases, as well as various switch products. Join us as we explore the unique characteristics and advantages of PBT GF30 material, its applications in the manufacturing of light bulb bases and switches, and how it contributes to the overall quality and functionality of these products. Stay tuned to discover more about this versatile material and its role in creating durable and reliable components for lighting and electrical applications.

Polybutylene terephthalate (PBT) is a thermoplastic polymer that offers a variety of properties making it suitable for a wide range of applications. Here are some key properties of PBT material:

-

Mechanical Strength: PBT exhibits good mechanical strength, including high tensile strength and stiffness, making it suitable for applications requiring structural integrity.

-

Heat Resistance: PBT has excellent heat resistance, with a high melting point and the ability to maintain its properties at elevated temperatures. This makes it suitable for applications exposed to heat.

-

Chemical Resistance: PBT is resistant to many chemicals, oils, and solvents, providing durability in challenging environments.

-

Electrical Insulation: PBT is known for its excellent electrical insulation properties, making it a popular choice for electrical and electronic applications.

-

Dimensional Stability: PBT has good dimensional stability, maintaining its shape and size even when exposed to varying temperatures.

-

Creep Resistance: PBT exhibits good creep resistance, meaning it can withstand constant stress over an extended period without deforming.

-

Weather Resistance: PBT is weather-resistant and can withstand exposure to UV radiation and harsh weather conditions without significant degradation.

-

Flame Retardancy: Some PBT formulations are available with flame retardant properties, adding a layer of safety to applications where fire resistance is needed.

Overall, the combination of mechanical, thermal, chemical, and electrical properties make PBT a versatile material used in various industries, including automotive, electrical and electronics, appliances, and more.

What part is PBT GF30?

PBT GF30 refers to a type of material composed of PBT (Polybutylene Terephthalate) reinforced with 30% glass fiber (GF). PBT is a type of engineering thermoplastic known for its high strength, stiffness, heat resistance, and dimensional stability.

When glass fibers are added to PBT resin, it enhances the material's mechanical properties, making it even stronger, stiffer, and more resistant to heat and chemical exposure. The addition of glass fibers also improves the dimensional stability and creep resistance of the material.

PBT GF30 is commonly used in various industries for applications that require high mechanical strength, dimensional stability, and resistance to heat and chemicals. It is often used in automotive components, electrical and electronics parts, industrial machinery components, and household appliances where robust performance is essential.

Download

-

拓扑新材料 PBT D0730NA.pdf

Download 拓扑新材料 PBT D0730NA.pdf